An Industrial Hub Endeavor Aims to End Period Poverty

A faculty-and-student team delivers solutions to a prevailing socio-economic problem, in collaboration with UN Women and ACTED.

In 2020, a study by Plan International estimated that around 66 percent of adolescent girls and women in Lebanon were no longer able to afford safe and hygienic menstrual care products. Since then, what become known as “period poverty” – the struggle that women face in trying to afford the products that help them manage their menstrual cycles – is still on the rise.

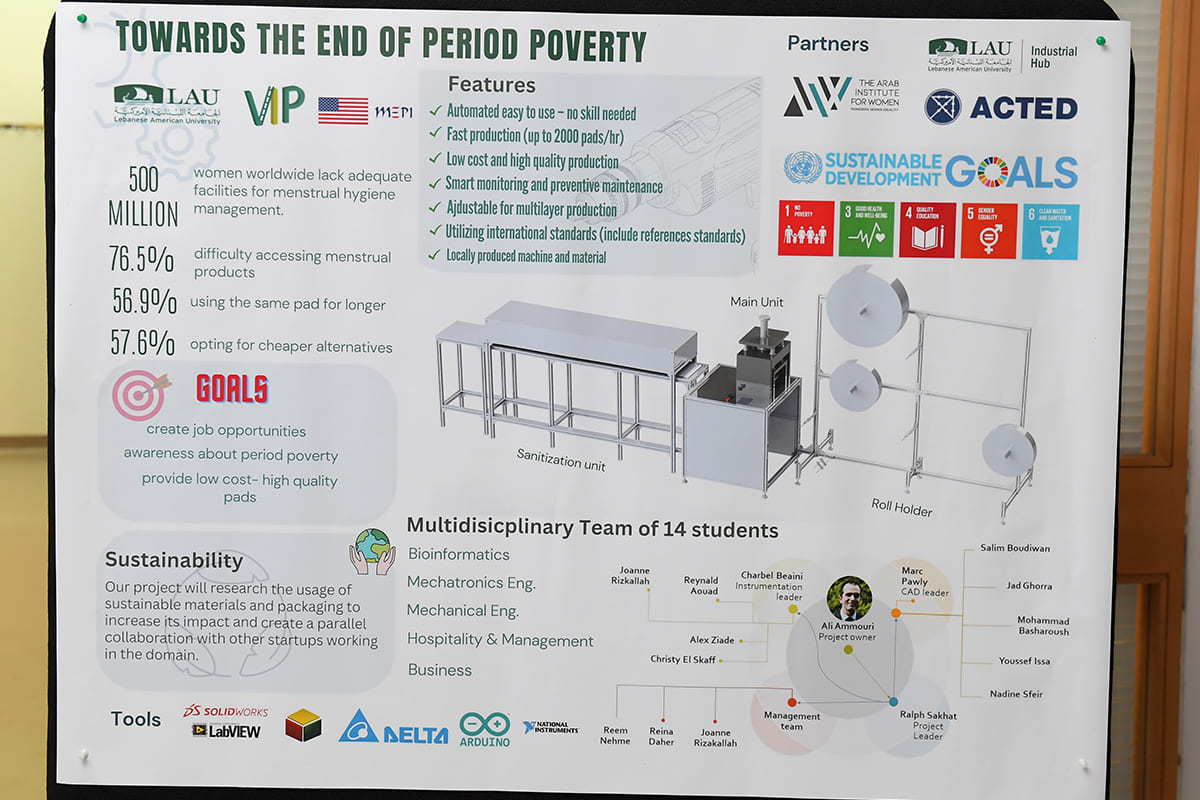

To make these products more accessible to women, a group of 15 LAU students – “the Padvocates” – is working on designing and assembling a machine that manufactures them, which, once launched, will be the first such unit to be designed and fabricated in the region.

The idea took root in an ongoing partnership with UN Women and ACTED, an international Non-Governmental Organization. The two joined forces shortly after the onset of the economic crisis to alleviate the impact of period poverty on vulnerable communities in Lebanon. With the help of several donors, they imported and delivered three manufacturing units of sanitary products to Tripoli, Beirut and Sidon, providing a cost-effective solution to underprivileged women.

The teams from UN Women and ACTED identified an opportunity to manufacture the unit locally, thanks to a connection with LAU’s Arab Institute for Women that directed them to the newly established LAU Industrial Hub (LAUIH).

“Our aim is to bridge the gap between the industry and academia by collaborating with industry partners to outsource their products and services to the LAUIH which aims at delivering these products through our faculty expertise, research capacity, student talent, and our state-of-the-art facilities,” said Assistant Professor of Practice at the School of Engineering Ali Ammouri, who is the director of the LAU Industrial Hub.

He also pointed to the USAID-funded Vertically Integrated Projects (VIP+) Program at LAU, which provides a framework for students from different disciplines to work together while collaborating on LAUIH industry challenges to provide cost-effective products and solutions. Last March, this design won at the Industry-Academia Day and the students presented their work at the Annual VIP Consortium in the US.

Shortly after Menstrual Hygiene Day on May 28, LAU hosted visiting teams from UN Women and ACTED on the Byblos campus, for the students to share progress on the fabrication of the machine. The visitors toured the Engineering Labs and Research Center and engaged in discussions with the team on their experience so far.

Fifth-year mechatronics engineering student Ralph Sakhat reflected on his journey of discovery, research and development throughout the project. “Learning from what the women and girls had to say during our research has been eye-opening for me, especially as we have come across some shocking numbers,” he said, adding that “our job as engineers is to solve problems, and this project has been very inspirational in that sense.”

“As a woman, I struggled first-hand from the continued rise of period-care products, and it has been very fulfilling for me to put my engineering skills to use for a cause that is very important to us,” said fourth-year mechatronics engineering major Joanne Rizkallah.

For Program Assistant at UN Women Nour Abdul Reda, localizing the manufacturing of the machine is intuitive: “In Lebanon, we have brilliant minds who shine across different sectors – why not work with the local talents to produce something we so desperately need?”

Sakhat explained how a locally manufactured machine is more cost-effective in the long term, since its maintenance and procurement of spare parts can be sourced locally, and saves the time and resources spent in communicating with international suppliers and waiting for shipments to arrive. “Since we are the ones who created the machine, we would be able to fix it,” he noted.

This collaboration opens many doors for the students on one hand and for the industry partners on the other, said Dr. Ammouri. He gave the example of a final year student project, a wash station, that was adopted by the Red Cross to help maintain hygienic practices at refugee camps. “The sky is the limit to the solutions that we can offer together with our students through the LAUIH,” he said.

Echoing this thought, Vice President for Business Development and Global Affairs Elie Badr hoped that this project will be “a landmark launch for the LAUIH, with many more to follow.”